Advancements in AI technologies

Technologies like Natural Language Processing (NLP) and generative AI (GenAI) have allowed computers to understand human language and to create new content based on the input received. These advancements enabled various new use cases for AI in manufacturing, as discussed in our second whitepaper in this series. However, new advancements promise even greater transformations.

Agentic AI

understands the context, autonomously makes decisions within specific parameters and executes actions. Within manufacturing, it can embed decision making directly into machinery.

Artificial General Intelligence (AGI)

AGI is the ultimate goal of advancements in AI technology, but, today, is still a theoretical concept. AGI would be capable of reasoning, problem solving and adapting to unforeseen circumstances across various domains. It wouldn’t be restricted to specific tasks or domains and could autonomously pursue goals, learn new things and adapt to different environments.

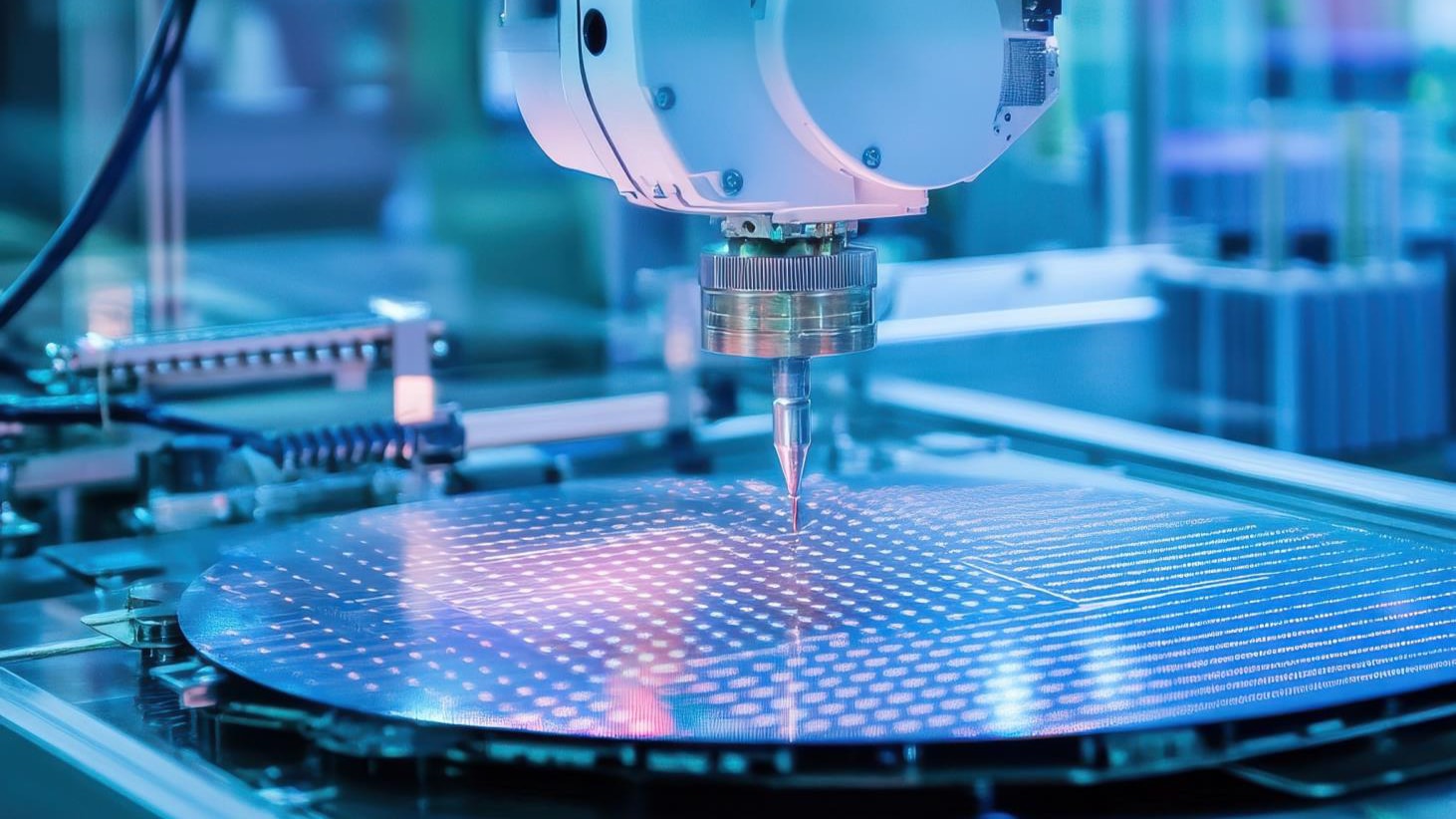

Dark/Lights-out factories

Facilities that operate fully autonomously without human intervention, typically in complete darkness as no human presence is required. AI enhances robotic capabilities and enables autonomous decision making. Its ability to integrate with IoT devices allows for real-time monitoring and adjustments. As AI technology advances, the efficiency and reliability of lights-out factories will increase.

Skill shifts concerning labour shortages

The integration of AI and automation in the manufacturing industry is creating a shift in resource demand. There’s an increasing need for workers skilled in AI oversight and maintenance, as well as complementary roles that require human creativity and problem solving. AI could also serve as a critical solution to Europe's labour shortage, particularly in blue-collar industries. By automating repetitive and physically demanding tasks, AI can help sustain economic growth while allowing human workers to focus on higher-value roles. Managing this shift in labour requirements will become more pressing as AI technology advances.

Business reinvention

According to PwC's 28th Annual Global CEO Survey, 53% of Belgian CEOs believe their companies won’t be viable beyond the next decade without reinvention. As highlighted in our second whitepaper, AI can be a key driver of business reinvention. Today, we already see this in how AI enables mass customisation without sacrificing efficiency and in how AI facilitates a "Product-as-a-Service" (PaaS) model, providing continuous support and maintenance that generates steady revenue streams. As AI capabilities advance, manufacturers will spot more and more opportunities to disrupt their offerings and reinvent the way they do business.

Increasing efficiency and accessibility of AI systems

As AI techniques continue to develop, such advancements are making these technologies more feasible for a broader range of applications. For many applications, particularly those involving language models, the primary costs are not in model training, but in inferencing – the process of using the trained model to deliver responses or perform tasks. This is where Small Language Models (SLMs) demonstrate their value. As hardware and software continue to advance in efficiency, we expect AI to become more accessible and impactful across the industry.

Your AI action plan

Four no-regret moves you can start with today.

Reflect on your long-term vision for AI: Imagine an automated future where AI’s deeply ingrained in every facet of your manufacturing process, driving innovation, efficiency and customisation to unprecedented heights.

Identify current pain points that AI could help address: AI offers a promising solution to issues of inefficient resource allocation, inconsistent quality control and rigid production processes. It enables smart systems to optimise operations, predict maintenance needs and adapt to market demands with agility.

Prioritise your use cases based on impact and feasibility: Focus on initiatives that promise significant ROI and align well with your strategic objectives and available resources. Start by deploying AI for high-priority solutions, such as predictive maintenance, which not only offers a significant impact, but is also practical to implement with existing technology.

Start small, scale fast: Begin with small, achievable AI projects that pave the way for rapid scalability. Learning from initial trials and quickly iterating them will make sure that AI solutions are well-integrated and scalable across your operations, enabling your company to scale fast while minimising risk.

Case: AI adoption at Exion Hydrogen

Exion Hydrogen produces reliable water electrolysers for hydrogen production. It understands that AI’s becoming essential and sees the potential it can bring to the company’s day-to-day work. Exion Hydrogen already uses ChatGPT for marketing activities, code translation and the creation of Mermaid syntax. It’s exploring it also for use in generating mechanical drawings and developing a chatbot for the organisation’s knowledge base. Beyond ChatGPT, Exion Hydrogen uses classical AI for categorisation of event logs. Going forward, the company sees a lot of potential in using AI for drafting piping and instrumentation diagrams (P&IDs) and electrical schemes, as well as in the cleaning and organising of unstructured data.

What does the future hold?

The future of AI in manufacturing has the potential to have an immense impact. From the realisation of fully autonomous lights-out factories to driving significant shifts in labour requirements. But this requires business reinvention and the increased efficiency and accessibility of AI systems. For manufacturers looking to get started with AI, it’s crucial to align strategic goals with practical use cases, prioritise based on impact and feasibility and start with small, scalable projects.

Download our fifth whitepaper

The future of AI

Artificial intelligence that drives real impact

Discover our generative AI Pathways

AI in Business

Artificial Intelligence isn't just a set of tools. AI heralds a new era.