In recent years, a majority of industrial companies have migrated to more complex ecosystems to boost and enhance their digital capabilities. Often featuring tighter vertical integration, these new ecosystems can drive efficiencies and real value, but they also require different approaches on how to support and manage IT (information technology) and OT (operational technology).

Today’s industrial companies need to change how they interact with, react to and provide services for their customers if they hope to obtain desired levels of value from the next wave of digitisation. At the same time, the ongoing COVID-19 crisis leaves these companies with no choice but to accelerate their digital transformation, and to do so in a smart and guided way.

About this paper

We sincerely believe that IT/OT convergence can bring important benefits to industrial companies making the digital transition. This paper provides insights for industrial companies into the challenges and benefits of IT/OT conversion, and lists some key factors needed to achieve overall better digital organisation.

Our expert team at PwC can help you identify business value creation by choosing and implementing specific digital use cases in your company by relying on a firmly established IT/OT converged organisation, and proposing the necessary change management.

We hope that this summary helps you to think critically about the role that IT/OT convergence can play in fully digitising your company and the impacts it will have on your day-to-day business, ranging from strategy to execution.

Challenges in IT/OT convergence

Changes in the digital application landscape have opened a window of opportunity for industry players to re-engineer the organisation of service providers, but efforts to innovate and digitise are often slowed down or impossible to execute because of the lack of a cross-IT/OT supporting structure and lack of vision on IT/OT collaboration. Both obstacles stand in the way of fully achieving smart manufacturing. Costs will be hard to manage, and added value will be difficult to realise. While local plant adoption remains a high priority, it is crucial to ensure system flexibility and that local initiatives also comply with global prerogatives.

Main challenges when IT and OT are not aligned

- Suboptimal collaboration and segregated strategies

- Heightened security risks through interlinked networks

- Over-reliance on single points of knowledge (vulnerability to staff departures)

- Complicating effects of vertically integrated technologies on business processes

- Incomplete IT/OT data integration (hindered ability to analyse data in real time)

Benefits of IT/OT convergence

IT/OT convergence allows your industrial company to create applications that efficiently combine information from the whole value chain, which in turn enables real-time reporting and decision making.

IT/OT convergence can leverage local shadow IT/OT applications that often result from hands-on experience and capabilities from local employees. Speeding up the digital transformation of your local shadow IT applications can result in a better adoption of new digital tools and the creation of success stories.

As a part of IT/OT convergence, legacy systems can be combined with new technologies, allowing you optimise operations through smarter and faster business decisions.

One of the crucial steps in achieving IT/OT convergence is allowing your company to have a clear view on the total applications landscape, thus lowering and minimising the risk of malfunctioning applications and security breaches.

Key success factors

Embrace transition to a secure, platform-oriented landscape

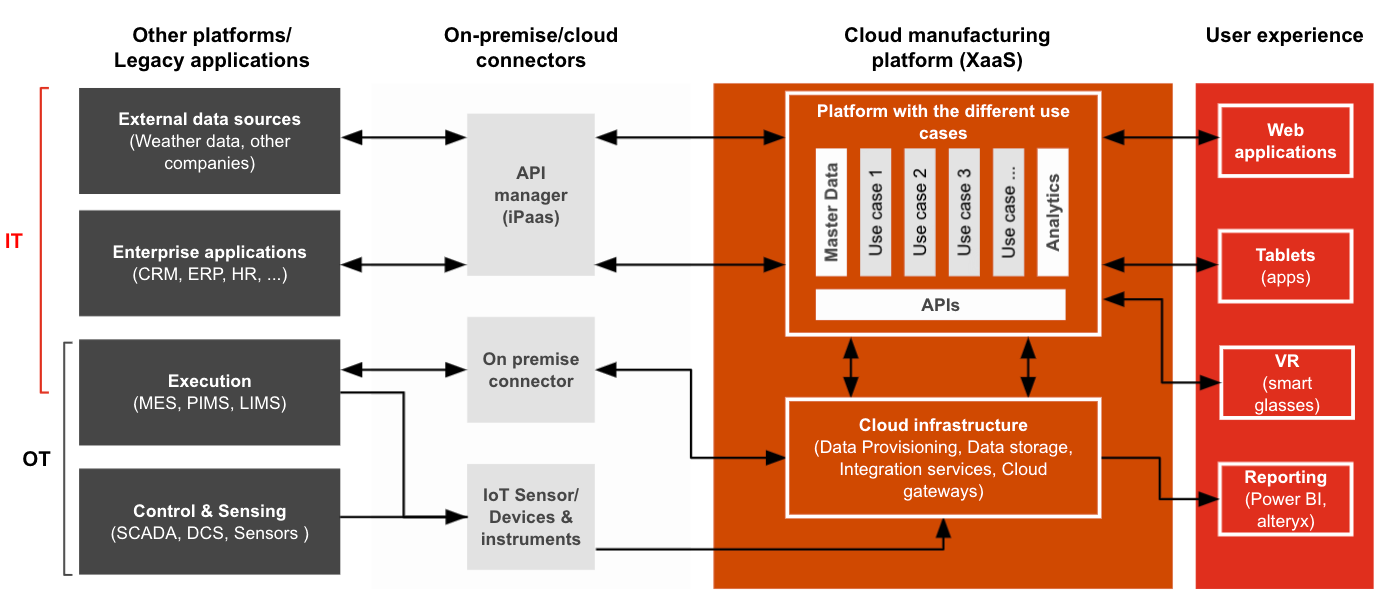

Whereas the current technology landscape is often fragmented, companies need to transition towards a platform-oriented landscape. By doing so, companies can leverage their platforms to enable use cases that have the same value generation, data needs, knowledge needs, and support and demand needs.

Transitioning to a platform-oriented landscape propagates data across enterprise systems and makes the data accessible when needed. An important prerequisite is that all data must be available from a single master source, and must be provided within a single view for the enterprise and partners.

High-level reference architecture IIoT manufacturing platform taking into account ISA 95 levels

Set up a data centre of excellence for optimum value

Building analytics capabilities are of key importance for optimising your production performance, reliability and reporting. A data centre of excellence will be the organisation that educates, trains and brings more innovative ways of working to your business, manufacturing sites and functional groups. It will also drive more data science innovation within use cases by sharing best practices and new methods of analysis and automation.

Build your delivery teams around a specific use case

In a platform-oriented landscape, vertically integrated applications will not be fully allocated to IT or OT, but instead will belong to the team responsible for the use case. All services and use cases need to be aligned with a target vision of a digital platform, keeping in mind the needs of end users. This also includes considering the user experience when designing the front-end of applications.

Give ownership to the business while maintaining an overview on the applications landscape

In making a digital transition, it is not enough to only address the technical developments. You also need to transform your organisation, culture and processes. It is important to keep some guiding principles in mind when designing processes related to IT/OT convergence.

The first requirement is a local entry point with the required knowledge of highly critical OT applications. Ideally, industrial companies will act proactively on a critical problem before an end user flags it. Second, industrial companies need to set up an architecture board to maintain a clear view on the applications landscape.

Download the report

Contact us

Partner Technology Consulting & Innovation, PwC Belgium

Tel: +32 495 59 08 40